Magnetic Grids In Housing

Drawer Type Magnetic Grates in Housing

Magnetic grate separators are an effective solution for removing metal contamination from various materials in different industries. Metal contamination in products can lead to serious health hazards and reputation loss for companies. Drawer type magnetic grates in housing offer an efficient and cost-effective way to remove metal particles from materials before they reach the final product. This technology is widely used in food processing, pharmaceuticals, chemicals, plastics, and other industries.

What is a Magnetic Grate Separator in Housing?

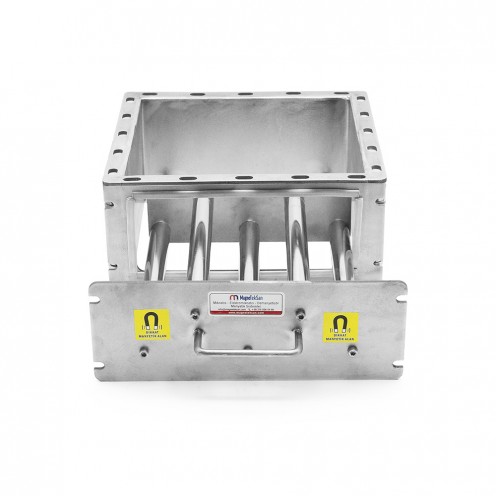

Magnetic grate separators in housing consist of magnetic grids mounted in a housing or frame. The magnetic grids are composed of a series of magnetic tubes or rods placed parallel inside the housing. The chassis is designed to allow the material to flow through the magnetic grids, which capture and hold metal particles while allowing non-magnetic material to pass through.

Working Principle of Magnetic Grid Separator in Housing

The principle of magnetic grate separators in housing relies on the magnetic force generated by the magnetic rods or tubes. As the material flows through the housing, metal particles are attracted to the magnetic rods and held tightly on the surface. Non-magnetic particles continue to flow through the housing and exit from the other end. The captured metal particles can be removed by manually or automatically cleaning the magnetic rods.