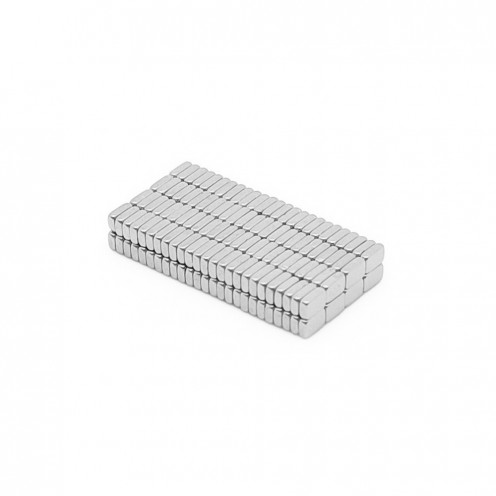

30x10x1.5 mm N35 Neodyum Magnet (Width 30 mm x Length 10 mm x Thickness 1.5 mm)

New

30x10x1.5 mm N35 Neodyum Magnet (Width 30 mm x Length 10 mm x Thickness 1.5 mm)

$0.86

With installments starting from $0.06!

- Stock: Sadece Teklif

- Model: MGK-NEK-35

- Category: Kare Dikdörtgen Neodyum Mıknatıslar

| Stock | : | Sadece Teklif |

| Model | : | MGK-NEK-35 |

| Category | : | Kare Dikdörtgen Neodyum Mıknatıslar |

Product Added to Cart

30x10x1.5 mm N35 Neodyum Magnet (Width 30 mm x Length 10 mm x Thickness 1.5 mm)

If you have questions about the product, you can contact our team before purchasing.

Product Added to Wishlist

30x10x1.5 mm N35 Neodyum Magnet (Width 30 mm x Length 10 mm x Thickness 1.5 mm)

The product has been saved to your list so you can access it later. You can turn the product into an order at any time by going to the favorites area. Have fun shopping.

⚙️ Updated Technical Product Information

| Feature | Value |

|---|---|

| ✅ Product Name | N35 Neodymium Magnet – Rectangular Type |

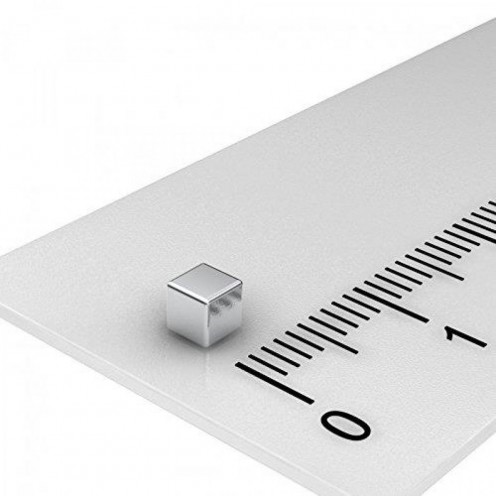

| ✅ Dimensions (Adjusted) | 30 mm (Width) × 10 mm (Length) × 1.5 mm (Thickness) |

| ✅ Shape | Rectangular Block |

| ✅ Material | NdFeB (Neodymium–Iron–Boron) |

| ✅ Grade | N35 |

| ✅ Coating | Ni–Cu–Ni (Triple-layer nickel coating) |

| ✅ Magnetic Pole Orientation | Through thickness (1.5 mm) surface-to-surface magnetization |

| ✅ Magnetic Flux Density (Br) | 4,000 – 5,000 Gauss (Standard N35 level maintained) |

| ✅ Coercive Force (HcB) | ≥ 10.8 kOe |

| ✅ Maximum Energy Product (BHmax) | 35 MGOe |

| ✅ Density | ≈ 7.5 g/cm³ (unchanged) |

| ✅ Maximum Operating Temperature | 80 °C |

| ✅ Corrosion Resistance | Medium – Protected by coating |

???? Mechanical Properties (Unaffected by Size)

| Feature | Value | Description |

|---|---|---|

| Hardness | ~600 HV | Brittle structure – handle with care |

| Compressive Strength | ~1000 MPa | High resistance on metal surfaces |

| Tensile Strength | ~75 MPa | Measured along magnetic axis |

| Thermal Expansion Coefficient | 6.5 × 10⁻⁶ / °C | Thermal stability is limited |

???? Magnetic Characteristics & Surface Area Analysis

| Parameter | Previous Value (25×8×2) | New Value (30×10×1.5) |

|---|---|---|

| Surface Area (magnetic face) | 25×8 = 200 mm² | 30×10 = 300 mm² (50% wider contact area!) |

| Thickness (magnetic axis) | 2 mm | 1.5 mm (thinner → sharper flux release) |

| Volume | 400 mm³ | 450 mm³ (+12% volume increase) |

| Estimated Pull Force | 500–700 grf | 600–800 grf (wider surface increases adhesion, but thin structure makes it easier to chip under vertical pull — surface grip improves but break risk increases) |

✅ Conclusion: This size provides a wider & flatter contact surface. The holding force spreads across the surface, but due to the 1.5 mm thinness, vertical magnetic engagement distance is sharp and short-range. This type of magnet is ideal for sensor triggers, surface mounting, and thin metal plate holding systems.

⚙️ Application Areas – Optimized for This Size

-

Ultra-thin magnetic click/lock mechanisms

-

PCB, sensor, Hall effect trigger systems

-

Thin metal panel securing systems

-

Modeling / drone accessories with lightweight magnetic latching

-

Magnetic switch faceplates

-

Hidden magnet slot cover mechanisms (boxes, panels, device lids)

⚠️ Critical Usage Notes (Specific to 1.5 mm Version!)

| Condition | Effect |

|---|---|

| Thickness is very thin → HIGH impact risk | ⚠️ Edge cracking may occur. Do NOT let it snap onto metal surfaces. |

| Magnetic direction parallel to surface → BROAD effective holding area | ✅ Sticks firmly to surface, best released by sliding motion. |

| Vertical pull | ⚠️ Very strong surface adhesion but due to thinness it may snap/crack instantly if forced straight upward. |

Specifications

| Dimensions | |

| Width | |

| Length | |

| Height | |

| Magnet Properties | |

| Coating | |

| Color | |

| Gaussian Value | |

| Magnet Attraction Distance | |

| Shape | |

| Tolerance | |

| Magnet Type | |

| Grade | |

| Max. Operating Temperature | |