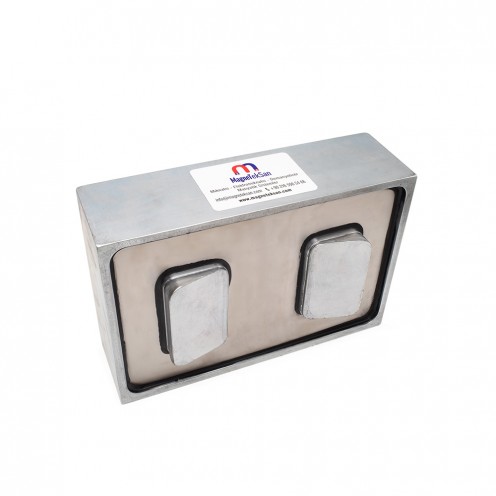

400x200x100 mm Rectangular Electromagnet - Sheet Metal Transport

With installments starting from $0.00!

- Stock: Sadece Teklif

- Model: MGK-E-12

- Category: Dikdörtgen Elektromıknatıslar

| Stock | : | Sadece Teklif |

| Model | : | MGK-E-12 |

| Category | : | Dikdörtgen Elektromıknatıslar |

| Quantity | Pack Price | Unit Price | |

|---|---|---|---|

| Stok Yok! | 100 Quantity | $0.00 | $0.00 |

Please contact us for larger quantities.

400x200x100 mm Rectangular Electromagnet - Sheet Metal Transport

400x200x100 mm Rectangular Electromagnet - Sheet Metal Transport

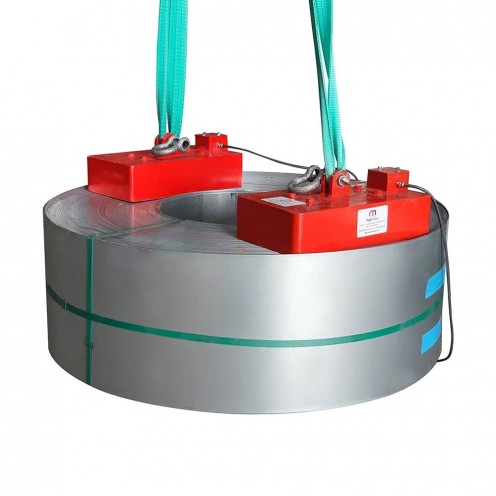

Sheet Metal Handling Electromagnets: Efficient and Reliable Metal Transport Solution

One of the innovations that advanced technologies have brought to the metal industry is sheet metal handling electromagnets. These electric magnets are used to lift large-scale sheet metal plates efficiently and safely through electromagnetic interaction.

Sheet metal handling electromagnets are devices that create a magnetic field using electrical energy. When electric current is applied, the electromagnet quickly creates a magnetic field, firmly holding the sheet metal plates. When the power is cut off, the magnetic field disappears, and materials are released.

The advantages offered by these electromagnets make sheet metal handling operations faster, more efficient, and safer. Here are the prominent features of sheet metal handling electromagnets:

- High Carrying Capacity: Electromagnets are typically equipped with powerful magnetic coils capable of producing high magnetic force. This allows them to easily carry large and heavy sheet metal plates

- Flexibility and Customization: Electromagnets can be manufactured in different sizes and shapes. This provides users with customized solutions suitable for their needs. Additionally, the magnetic force and carrying capacity of the electromagnet can be adjusted by controlling the electric current, allowing optimization for different materials and applications

- Precise Control and Safety: Control of electrical energy allows precise adjustment of the electromagnet's magnetic force. This provides controllability during material handling and offers a safe working environment

- Efficiency and Productivity: Sheet metal handling electromagnets operate faster and more efficiently compared to manual labor. This saves time in work processes and increases productivity

- Minimizing Material Damage: Electromagnets cause minimal material damage during gripping and carrying sheet metal plates. Through precise control of magnetic force, sheet metal plates are properly positioned and safely transported. This minimizes material damage, reducing costs and improving quality

Sheet metal handling electromagnets have a wide range of applications in the metal industry

They are preferred in many areas from the automotive sector to shipbuilding, from construction projects to iron and steel production. Their robust and durable structure provides long-term use and minimizes maintenance requirements.

The efficiency, safety, and flexibility that electromagnets bring to metal handling processes provide businesses with a competitive advantage. Efficient work processes, reduced labor costs, and higher productivity help companies stand out in competitive markets.

In conclusion

Sheet metal handling electromagnets are a safe and efficient metal handling solution powered by electrical energy. Thanks to their flexibility, precise control capabilities, and high carrying capacity, they have a wide range of applications in the metal industry. These electromagnets improve work processes while minimizing material damage and increasing productivity.

Specifications

| Dimensions | |

| Width | 151-200 mm |

| Length | 251-500 mm |

| Height | 76-100 mm |

| Magnet Properties | |

| Coating | Paint |

| Color | Red |

| Gaussian Value | 7000-8000 Gaussian |

| Shape | Rectangular |

| Strenght | 75-100 kg |

| Tolerance | ± 1 mm |

| Magnet Type | Electric |

| Max. Operating Temperature | 100°C |

| Material Properties | |

| Coating | Stainless |

| External Material Feature | Steel |

| Tolerance | ± 0,1 mm |

| Exterior Material Quality | 304 Quality Stainless |

| Sealing | Yes |