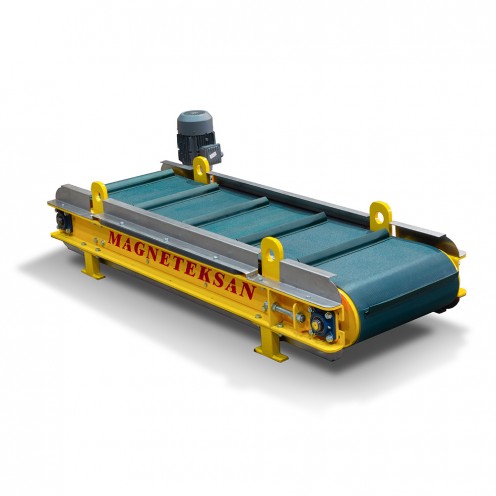

Automatic Self-Cleaning Overband Magnetic Separator for Cement Plants – 1200 mm Belt Width, Y35 Ferrite Magnet, 35 cm Suspension Height

With installments starting from $0.00!

- Stock: Sadece Teklif

- Model: MGK-PL-200

- Category: Otomatik T. Plaka Mıknatıslar

| Stock | : | Sadece Teklif |

| Model | : | MGK-PL-200 |

| Category | : | Otomatik T. Plaka Mıknatıslar |

Automatic Self-Cleaning Overband Magnetic Separator for Cement Plants – 1200 mm Belt Width, Y35 Ferrite Magnet, 35 cm Suspension Height

Automatic Self-Cleaning Overband Magnetic Separator for Cement Plants – 1200 mm Belt Width, Y35 Ferrite Magnet, 35 cm Suspension Height

In cement production lines, clinker, limestone, clay, additives, and various types of aggregates conveyed on belt conveyors inherently carry a risk of metal contamination due to the nature of the process. Such contamination can cause severe damage to crushers, mills, elevators, bunker feeding equipment, and conveyor systems, leading to unplanned shutdowns and costly maintenance operations. Since production continuity is critical in cement plants, belt-mounted automatic self-cleaning magnetic separators (overband separators) are among the most effective solutions for metal recovery and conveyor line protection.

Designed for 1200 mm belt width, this separator operates without interrupting the material flow on the conveyor. Thanks to the high magnetic field intensity generated by the magnetic system, it captures ferromagnetic contaminants within the material stream such as iron, steel, wires, bolts, screws, and sheet metal fragments. The captured metal pieces are continuously conveyed by the automatic cleaning belt and discharged at a predefined point (side discharge or into a separate collection chute). This eliminates the need for manual cleaning and ensures a safer and more sustainable operation.

What does automatic cleaning provide?

In conventional magnetic systems, metal accumulation on the magnetic surface may lead to reduced performance over time. In automatic self-cleaning overband systems, captured metal is discharged continuously without waiting, resulting in the following advantages:

-

The magnetic surface remains consistently efficient

-

Operator intervention is minimized

-

Metal separation is carried out without stopping the conveyor

-

Maintenance and cleaning times are reduced

-

Occupational safety is improved (reduced risk during manual metal removal)

Typical application points in cement plants

The 1200 mm belt-mounted automatic self-cleaning separator provides high efficiency especially in the following areas:

-

Limestone and clay conveying belts (before and after crushers)

-

Raw material feeding lines

-

Clinker transport conveyors

-

Coal and alternative fuel conveying belts

-

Final product lines before packaging (contamination control)

-

Transfer points with a risk of scrap or recycled metal contamination

In these applications, metal removal is critical not only for product quality but also as a protective safety layer for high-value equipment such as crushers, roller presses, and mills.

Proper positioning with Y35 – 35 cm suspension height

In this configuration, the 35 cm suspension height defines the operating distance of the separator above the conveyor belt. The suspension height is evaluated together with parameters such as metal size and weight, material bed depth, and belt speed. Correct suspension height selection:

-

Improves metal capture performance

-

Maintains a safe clearance without disturbing material flow

-

Contributes to more stable, vibration-free mechanical installation

Mechanical structure and process compatibility

Overband separators are designed with housings, frames, and protective covers suitable for heavy-duty industrial conditions. Cement plants require robust mechanical structures due to high dust levels, continuous operation, vibration, and occasional impact loads. In such applications, the separator is mounted using suspension brackets, aligned according to the conveyor geometry, and the discharge direction is adjusted based on site-specific conditions.

Why is it the right solution for a 1200 mm belt?

A 1200 mm belt width is commonly used in cement plants for high-capacity conveying systems. When this separator is correctly matched to the belt width, it provides:

-

Reduced risk of metal bypass at belt edges

-

More stable separation across wide material beds

-

Continuous metal separation even in high-tonnage applications

Tangible benefits for plant operation

-

Reduced unplanned downtime: Prevents failures caused by metal contamination

-

Lower maintenance costs: Minimizes wear and impact-related damage

-

Stable product quality: Keeps unwanted metal out of the process

-

Improved occupational safety: Reduces manual cleaning and intervention

-

Operational efficiency: Continuous separation suitable for 24/7 operation

Conclusion

For cement plants, the 1200 mm belt-mounted automatic self-cleaning magnetic separator ensures continuous control of metal contamination on high-capacity conveyor lines, protecting equipment and strengthening production continuity. When correctly positioned with a 35 cm suspension height (Y35), it delivers efficient and reliable metal separation tailored to the operating conditions of the line.

Technical Specifications

-

Application: Cement plant conveyor line

-

Type: Belt-Mounted (Overband) Magnetic Separator

-

Cleaning System: Automatic Self-Cleaning

-

Belt Compatibility: 1200 mm belt width

-

Configuration: Y35

-

Suspension Height: 35 cm

-

Mounting: Suspended frame above conveyor

-

Discharge Direction: Side discharge / collection chute (optional)

-

Operation: Continuous industrial duty (24/7)

-

Housing / Frame: Heavy-duty industrial construction

-

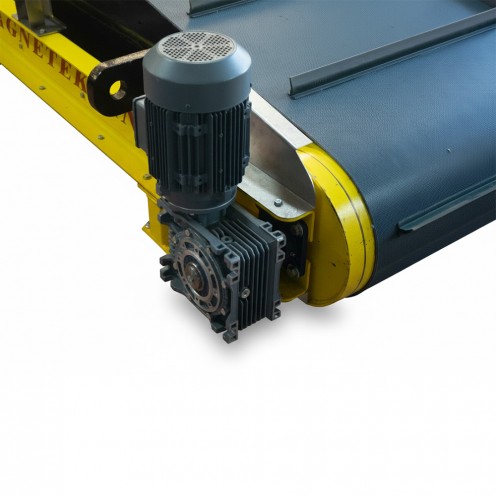

Options: Protective covers, custom frame design, alternative discharge directions, variable speed–gearbox selections

Specifications

| Dimensions | |

| Width | 251-500 mm |

| Length | 1000 mm + |

| Height | 51-75 mm |

| Magnet Properties | |

| Coating | None |

| Color | Black |

| Gaussian Value | 5000-6000 Gaussian |

| Magnet Attraction Distance | 30-35 cm |

| Shape | Rectangular |

| Strenght | 50-75 kg |

| Tolerance | ± 0,1 mm |

| Magnet Type | Ferrite (Oxide) |

| Grade | Y35 |

| Max. Operating Temperature | 220°C |

| Material Properties | |

| Color | Yellow |

| Complete Stainless | Yes |

| External Material Feature | Stainless |

| Tolerance | ± 0,1 mm |

| Exterior Material Quality | 304 Quality Stainless |

| Sealing | No |